You may also want to consider that a moving vehicle will put more load on a tube than a stopped vehicle. The load will spread out over more than one tube when 2 or more tubes are in contact with the ground/rocks/etc. Your vehicle will be moving, with many tubes in the roll cage supporting constantly changing loads during the roll. In a real rollover, the weight of your vehicle will not be a static load on just one tube. We hope you find this information helpful and that you don’t consider it to be any sort of approval of your design. This example is only showing how you could consider an isolated load on one part of your roll cage.

#Rec tube weight chart full#

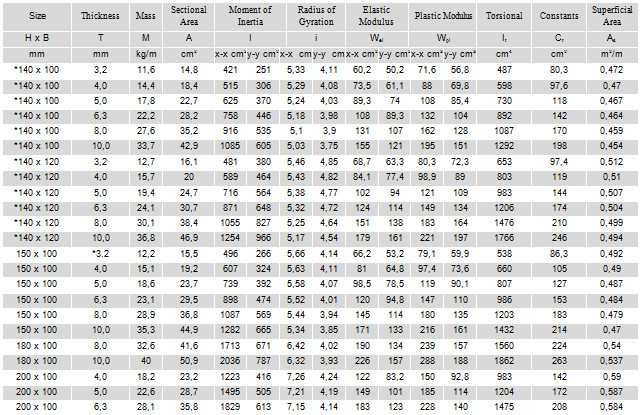

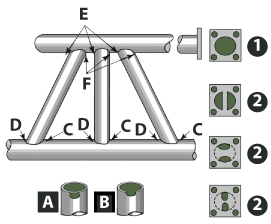

This calculator is based on many assumptions and “worst-case” criteria, so we recommend you read the whole page to get a full understanding of what these numbers actually mean and why we should consider them during roll cage design. This cage is just a simple example for teaching purposes, we don’t recommend you build a cage like this. This calculator assumes the load is in the center (worst case for stress), and distributed about 1/3 of the tube length (highlighted in red). In this example, we are assuming we will triangulate the rear to pieces so that they are shorter than the roof member, and also assuming that a front stinger (not shown) will prevent the front fender bars (long pieces on the left) from ever being hit directly. We chose the longest tube that is likely to hit during a roll (blue). The red arrow in the picture below is the load, maybe a rock or a stump. Don’t forget that putting hard metal close to occupants is very dangerous, so the use of proper seating, restraints, padding and helmets should always be considered. The safety factors use the numbers in the table below for strength.

Square tube assumes bending with one side parallel to the load (think square vs diamond). Loading in the middle of the longest tube is a worst case for stress on a cage member. Vehicle load is a static distributed load in the middle of the longest tube and is 1/3 the tube length. Material is nominal size (material is commonly under nominal size, but within material geometry specs, like. 095 wall is actually stronger for bending loads! You can also look at individual parts of a roll cage under load, but please understand that evaluating roll cages is work done by trained professionals and any evaluation you do on individual parts does not indicate the overall safety of the structure. Type them both into our calculator, and check other sources if you still aren’t sure. But you look at the thin wall on the 1.75x.095 and decide that light junk can’t be as strong as the 1.25 solid bar, right? Wrong. You pick them both up and look at them, and they both feel pretty beefy. For example, lets say your local metal distributor has 1.75x.095 tube and 1.25 solid bar on sale from some huge bulk purchase that fell through with another customer.

#Rec tube weight chart how to#

You should use this calculator to compare materials, diameters, and wall thicknesses to find out how to make your designs safer. This will typically result in the structure failing as a safety device. Pressure level that will fracture a material.

0 kommentar(er)

0 kommentar(er)